|

IN DAILY LIFE Today, Aluminum profiles have become a part of our daily life. To the majority of designers it is a pleasant convenience. For instance, it is used for furniture, finishing profiles and household appliances (spoons, keyboards, knives). |

|

ON THE ROADS Aluminum profiles are slowly replacing traditional materials and structures. The key advantages are light weight and high durability, but other characteristics are also important as well, such as resistance to corrosion and the possibility of 100 % recycling. In the food industry. |

|

ELECTRICAL ENGINEERING Aluminum profiles often allow a combination of design and technical advantages. Aluminum is a good heat and electrical conductor, and features good reflection characteristics in the range of visible light and infrared spectrum. Moreover, Aluminum shields against electric and magnetic fields. |

|

IN THE SEA Aluminum profiles in the sea are highly valued for their light weight, high durability, and resistance to corrosion. As usual, manufacturers have gained their biggest profits due to Aluminum’s characteristics of easy moulding, and this simple processing operation offers many interconnection possibilities. |

|

IN MANUFACTURING Tools for manufacturing can be produced easily and at an optimal cost. For those intending to test ideas and structural solutions, this technology allows them to set their starting point at prototyping. For instance, Aluminum is used for façade systems, doors, windows, indoor partitions and balcony systems. Aluminum is used as a raw material for the production of 0.004 µm foil (by rolling) and sheets (by forging). Aluminum -coated steel is protected against corrosion. Aluminum coating is also applied on ordinary mirrors and the mirrors of optical telescopes, and is used in melting steel or cast iron (as a reducing and deoxidising agent). Aluminum powder is used in the production of porous concrete, foil is used in the packaging of food products, powder is used in the industry of paint and varnish, and in the manufacturing of various types of heat exchangers. |

|

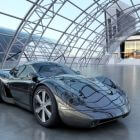

IN THE AUTOMOTIVE INDUSTRY In vehicles, Aluminum often replaces steel elements. It is absolutely possible to reduce the weight of a car by 100 kg: it means that, for instance, 182 kg of steel is replaced by 82 kg of Aluminum . The lower weight of cars is more cost efficient and allows saving 640 litres of petrol, corresponding to 23,000 MJ. |